Applications of fiber reinforcement for sustainable and future-proof infrastructure

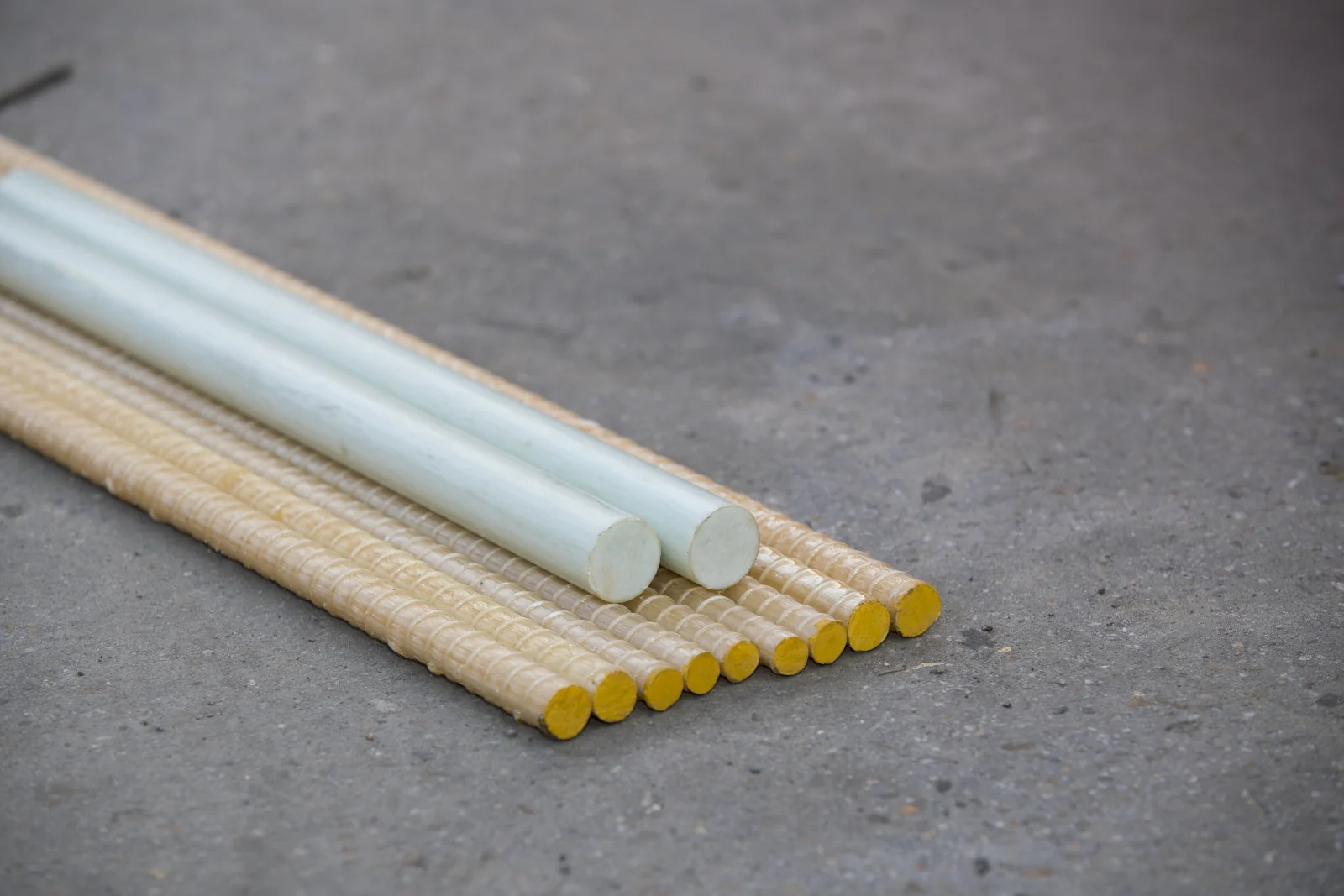

We often get this question from buyers who are considering fiberglass as an alternative to traditional materials, particularly steel. Steel is widely used in construction because of its high tensile strength, which can reach nearly 60,000 psi. However, in terms of strength-to-weight ratio, fiberglass performs significantly better than steel. Fiberglass offers the same strength as steel but is more flexible, making it impact-resistant. In addition, fiberglass weighs only 25 percent of what steel weighs while maintaining the same strength.

Furthermore, fiberglass is stronger than steel in the longitudinal direction, making it ideal for load-bearing applications such as loading platforms. For this reason, many industries request fiberglass, as it is stronger and lighter than steel. Moreover, steel has several other disadvantages that make fiberglass an even better alternative.

How strong is fiberglass compared to steel?

How strong is fiberglass compared to steel? Fiberglass is actually stronger than steel. This means that when you have a 25 mm diameter steel reinforcement bar, it’s not necessary to replace it with a thicker fiberglass reinforcement bar. In some cases, you can even reduce the thickness compared to steel bars.

Advantages of fiberglass compared to steel

| Property | Fiberglass (GFRP) | Steel |

|---|---|---|

| Corrosion resistant | ✅ Yes | ❌ No |

| Lightweight | ✅ 4 times lighter than steel | ❌ Heavy |

| Non-magnetic | ✅ Yes | ❌ No |

| Low maintenance | ✅ Yes | ❌ No |

| Long lifespan | ✅ Up to 100 years | ❌ More limited |

| Environmentally friendly | ✅ Recyclable | ❌ Not always |

Thanks to these advantages, fiberglass dowels and tie-bars or rebars are often used in constructions where durability and minimal maintenance costs are crucial.

Applications for

Fiberglass dowels and rebars are particularly suitable for applications involving heavy loads and exposure to moisture, electromagnetic fields, or chemicals. Some applications include:

Container terminals

Think of container terminals or distribution centers where heavy equipment is constantly in use.

Road Construction

Sustainable solution for road construction by reinforcing concrete in roads, exits, and entrances.

Bus lanes and BRT (Bus Rapid Transit) lines

For heavily used public transport infrastructure, reliability and low maintenance are essential.

Industrial estates

Reduce wear from heavy traffic and mechanical stress, and resistant to chemical influences.

Runways and taxiways (aviation)

Corrosion resistance and minimal electromagnetic interference are important advantages.

Tram and railway crossings

Fiberglass is non-conductive and therefore safe to use near railway infrastructure.

Frequently asked questions

Fiberglass reinforcement has a lifespan of up to 100 years, requires less maintenance, and contributes to CO₂ reduction in construction projects.

Fiberglass dowels are a sustainable alternative to steel: they do not corrode, are up to 4 times lighter, and reduce CO₂ emissions in construction. Thanks to their high tensile strength and long lifespan, they enhance the performance of concrete structures in heavily loaded areas such as roads, bridge decks, parking lots, and loading and unloading zones. This contributes to a longer service life and lower maintenance costs of infrastructure.

Fiberglass dowels have four times higher tensile strength compared to steel dowels. In addition, they do not rust and are significantly lighter in weight. Thanks to these properties, they are ideally suited for heavy-duty applications such as roads, bridges, terminals, and other infrastructure where durability and reliability are essential.

Free Sample | Quote Request

Are you interested in a quote or free samples of our fiberglass dowel baskets, dowels, rebars, or T-forms? No problem, request your free samples or quote today!

Contact us

If you have any questions about us or our products, please contact us, and we will be happy to assist you.