The question that regularly comes up during introductory talks with Fiber Dowels is why is fibreglass really better than steel? Or what exactly is this going to deliver for our company or my road construction project?

We would be happy to explain this to you in person in an interview. However, we are trying to explain it through this first blog about fibreglass dowels and fibreglass Rebars. This blog will discuss the first and perhaps most important advantage: “cost savings”.

Of course, the traditional steel dowels size 25/600 or 25/500 or other sizes with coating provide power transmission between concrete slabs and thus ensure driving comfort. Due to the casing, the dowel does not adhere to the concrete. This allows movements in the longitudinal direction of the dowel: the hardening can therefore shrink and expand. Horizontal movements in the transverse direction and vertical movements of boards in relation to each other are prevented by the dowels.

But to place these, the dowel first goes a long way. Steel dowels are often either stored or delivered directly to a project. Your employees then have to move it to the desired place. Eventually this dowel ends up in the hands of an employee who is active in the concrete and who drills the dowel into the pavement or he makes sure that it is applied on top of a basket. On average, your employee has the dowel fixed 5 times before it can be drilled or fitted.

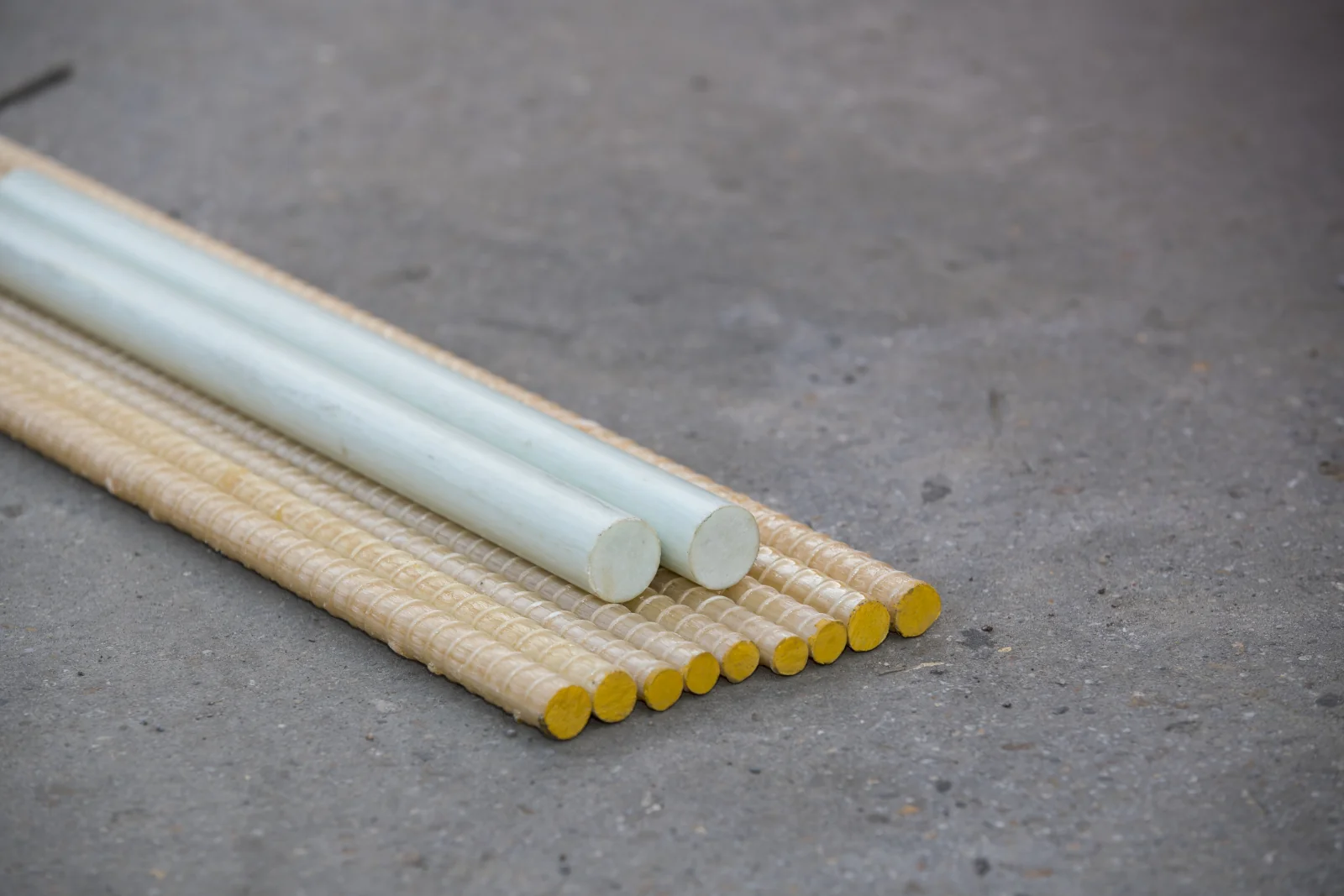

Why not look at a possibility to make this as easy as possible by means of a lighter fiberglass dowel. In this way, you will save on transport costs in the first instance. You can choose to have dowels in stock, so that you never miss out. The fiberglass dowels and fiberglass rebars, are suitable to move in a trailer or even in a van. Besides that our own developed dowel baskets and rebar baskets makes it way easier to place the products into the project.

But secondly, your employee will be able to move 4 times more dowels at the same time. A steel dowel quickly weighs 4 times as much as a fiberglass dowel. The comparison between steel rebars and fiberglass rebars is roughly the same. In 2024, it is already become more and more important to work in a job-friendly manner. If this also results in cost savings and satisfied employees, then if it’s up to us it’s worth a try!

Curious about the other advantages of the Dowels or Rebars? In our 2nd blog we will discuss another important advantage of choosing Fiber Dowels.