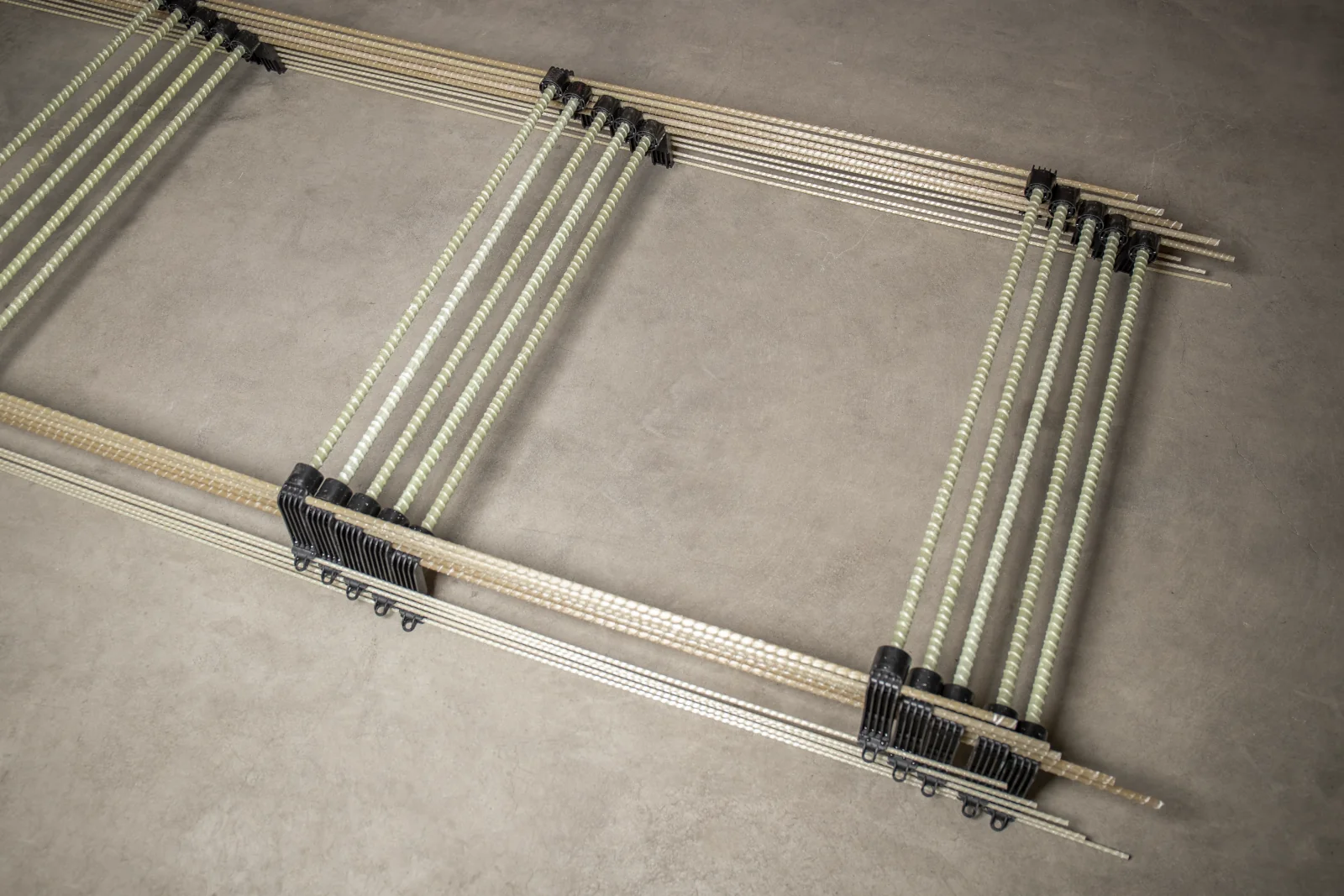

Lightweight and durable rebar baskets

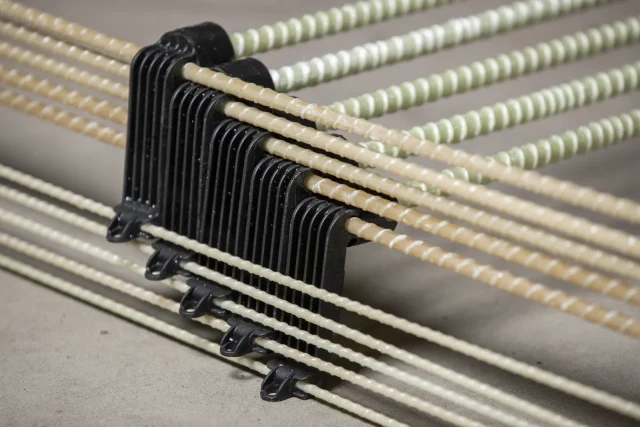

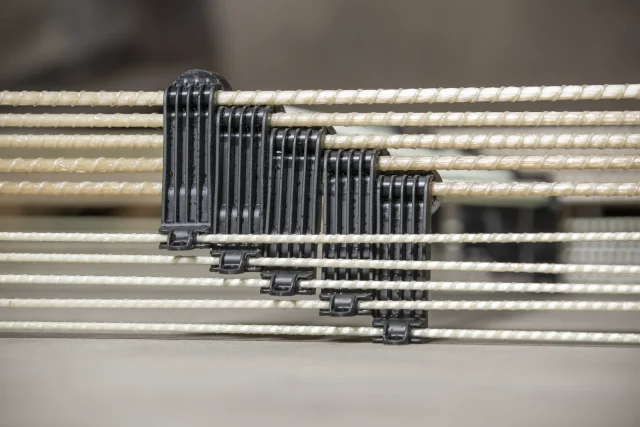

Fiber Dowels introduces the first fiberglass rebar baskets, which are lighter, more durable, and easier to install than steel rebar baskets. These patented coupling rods baskets are, like the dowel baskets, easy to transport and stack, ensuring that no empty space is moved. Because the baskets can be stacked, an employee can place 50% more baskets compared to the steel variant. Additionally, no machines are needed to move the materials on the project.

Applications and application areas of our rebar baskets

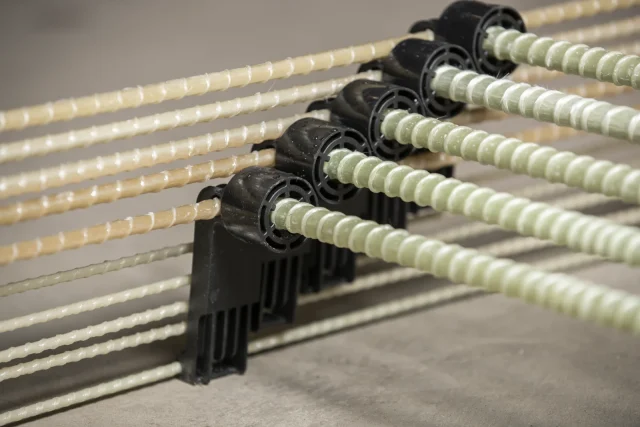

Fiberglass rebar baskets are used in the longitudinal joints of concrete pavements. Rebars prevent concrete slabs from moving apart from each other. The purpose of the rebar baskets is to keep the rebars at the correct height and distance. The profiled bars are applied adhesively, thus connecting the slabs in the concrete pavements and transferring tensile forces. The diameter and spacing are determined at the time of overall design.

There are also other products that can be used such as fiberglass dowel baskets, fiberglass rebars, fiberglass dowels and Fiber Dowels T Form.

The advantages in a glance

The fiberglass rebar baskets, like our previously patented product, the dowel baskets, offer numerous advantages. Here are some of the key benefits:

Corrosion

One problem with steel is corrosion. Steel reacts with water, causing rust. This rust weakens the steel and makes it less durable. Fiberglass, on the other hand, is not susceptible to any form of corrosion, which keeps it stronger and more durable.

Weight

Since fiberglass is generally up to four times lighter than steel, it allows for easier and faster installation. An employee can easily carry five baskets at once. Additionally, this demands less physical effort from the worker, reducing labor strain. This helps maintain employee satisfaction.

Environment

Producing and recycling fiberglass is more environmentally friendly than producing the steel version. For example, the steel version releases more CO2. This, coupled with the corrosion resistance of fiberglass, makes for a greener and more sustainable product.

Technical specifications

Fiberglass is not only an environmentally friendly choice, but also a material that excels in lightness and durability, with even more advantages over steel. With a high tensile strength of 1000 MPa and a composition consisting of 70% fiber, it delivers exceptional performance. Moreover, fiberglass also does not interfere with communication lines making it particularly suitable for airfields and container terminals.

Curious about the technical specifications compared to steel? Check out our Fiberglass VS Steel comparison to learn more!

| Artnr | Diameter | Lenght | Height | Distance in between | |

|---|---|---|---|---|---|

| Fiberglass rebar baskets 800/16 | GV-KR80016 | 16mm | 3,3m, 2,8m | 10cm | 75cm, 100cm, 125cm |

| Fiberglass rebar baskets 600/16 | GV-KR60016 | 16mm | 3,3m, 2,8m | 10cm | 75cm, 100cm, 125cm |

Projects

The fiberglass rebars can be applied to many projects and have a positive impact here. Below are several leading projects where fiberglass tie rods have been applied: